We make sustainability happen.

What’s the DaVinci difference? Good question—it’s not just our engineering experience, or our knack for finding innovative solutions. It’s using not just our heads, but our eyes, too. Where others see waste, we see opportunities for sustainable manufacturing that helps organizations achieve their goals while helping our planet—a symbiotic relationship where everybody wins.

Materials

We offer three categories of materials to cover a wide range of applications. We also choose to use our own polymer technology—this takes more effort, but we prefer this because for one, we’re pretty particular. More importantly, it gives us a detailed understanding of a polymer’s potential to achieve maximum performance for its application, and more control over quality. The result: you get exactly what you need.

Design & Development

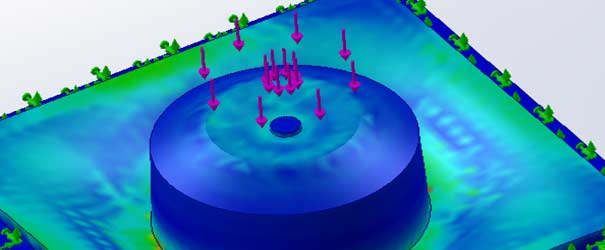

We start with an in-depth understanding of the functionality of a product and how our parts interact within that system. Using the Solidworks platform, we can conceptualize and design in 3D, and analyze designs in real-time to verify performance attributes. It means we can try anything and everything. And believe us, we do.

Prototyping

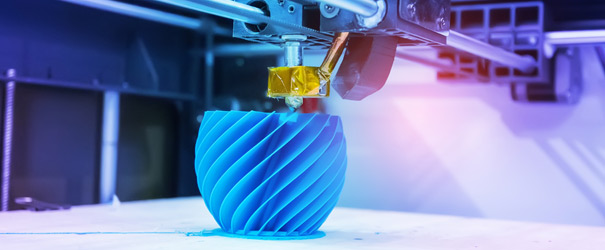

An optimum prototype process allows us to refine, test, validate and produce parts on time simulating production. We also offer 3D modeling capabilities, finite element analysis, and work with clients to finalize concepts prior to prototyping the proposed product. The process can include a rapid 3D print, higher surface quality SLA, or CNC machine plastic molds. We also employ the CNC machine process of aluminum tooling to produce a higher quality and quantity of samples that mimic the actual production process.