Mother nature uses less of everything. So do we.

DaVinci Molding is more than smart engineering and solutions for sustainable parts. It’s a vision for a better way to go about business—a new, thoughtful model where manufacturers use resources and waste wisely, with partnerships that create opportunities for sustainable practices that address global warming. Welcome to a better world of sustainable parts.

Introducing ENVIROBLE™

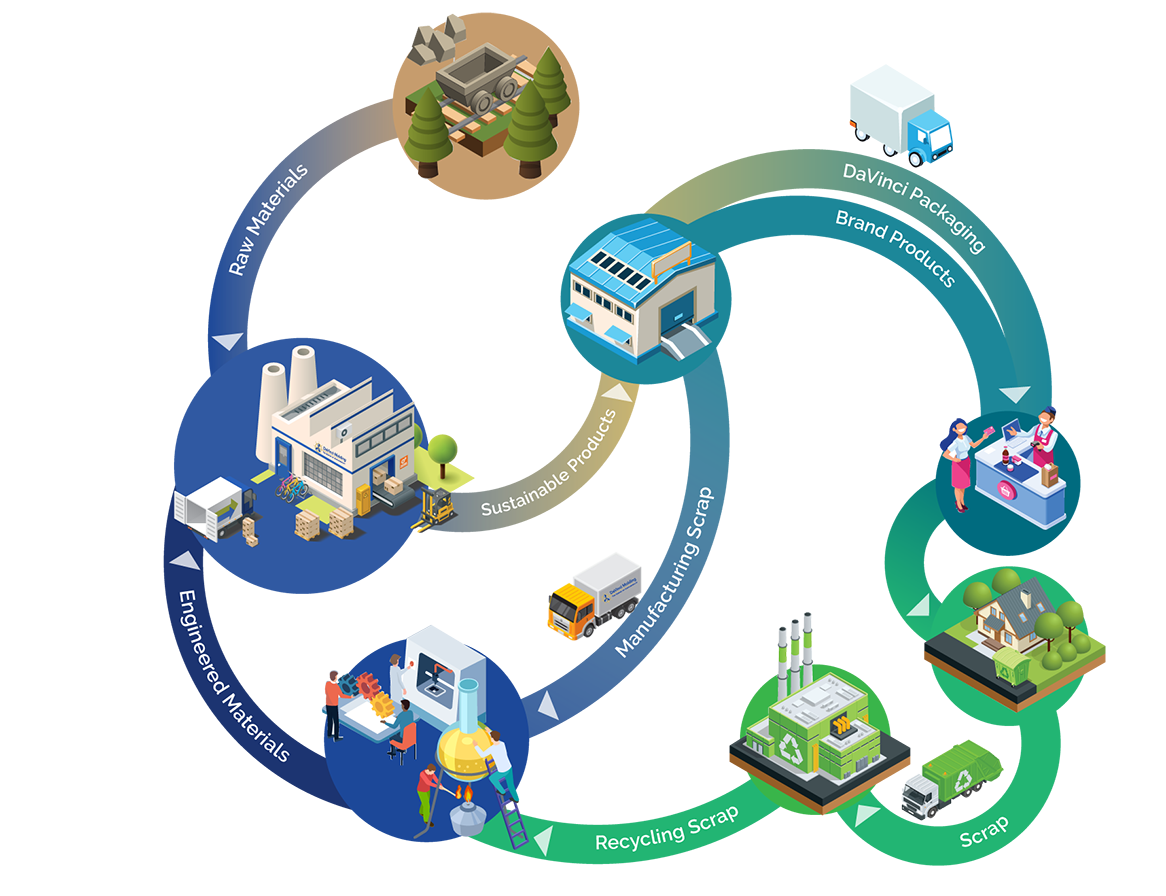

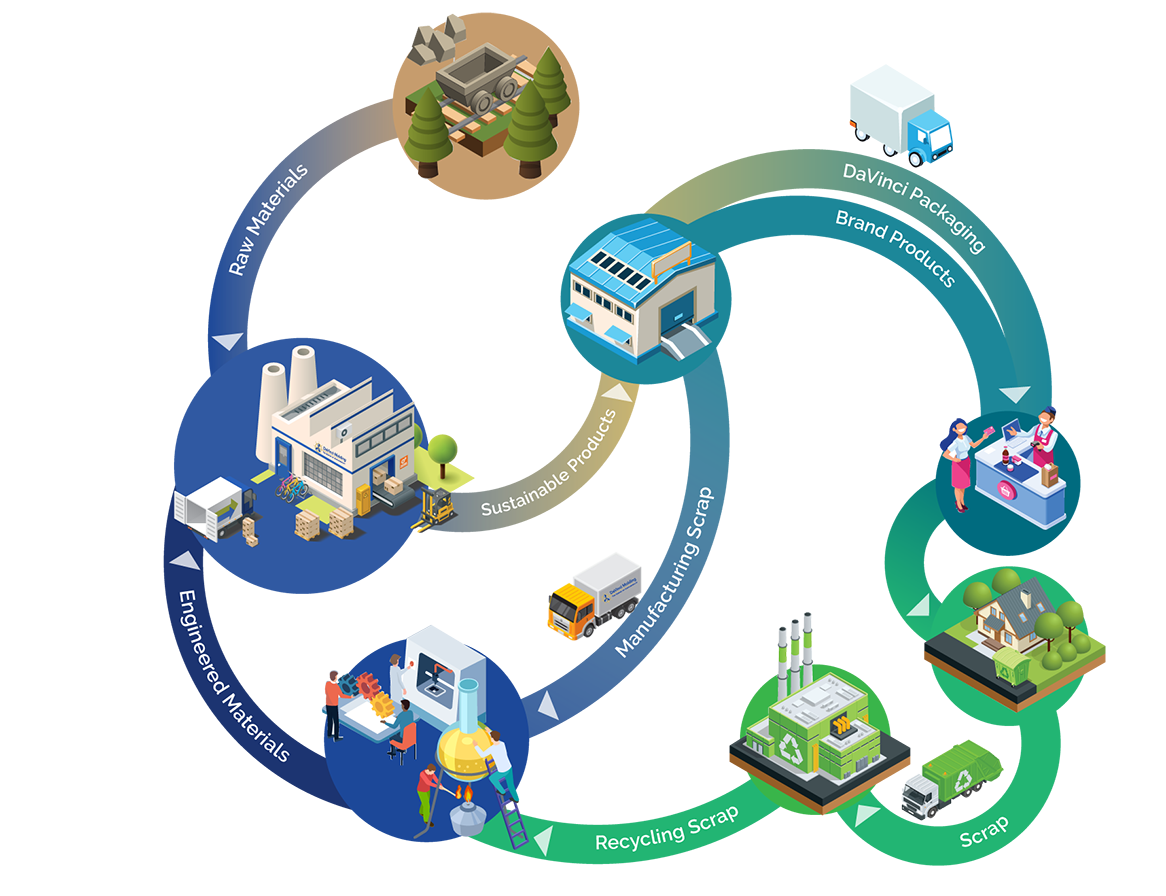

ENVIROBLE™ is a new, innovative approach to sourcing parts. Invented by DaVinci, Enviroble provides a full-circle system for the processing and conversion of scrap to finished sustainable products. By reusing resources, ENVIROBLE reduces carbon production and landfill volume, and allows your organization to quickly respond to the demand for sustainable practices.

DaVinci Molding

Here is where DaVinci genius begins. Designs for the parts you need are tested and validated to become prototypes, and ultimately, finished sustainable parts.

Companies in food, automotive, consumer products and industrial sectors get the sustainable parts they require for their goals.

Instead of plastic waste going to landfills, DaVinci uses manufacturing waste to create sustainable parts for a much more environmentally friendly approach.

Waste from recycling plants is also collected and used for Davinci recycled parts.

Our expertise with materials allows us to use dissimilar materials [PET, etc.] to engineer sustainable parts for every imaginable use.

Major brands in a variety of sectors rely on us to provide packaging, parts and components for their products.